We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

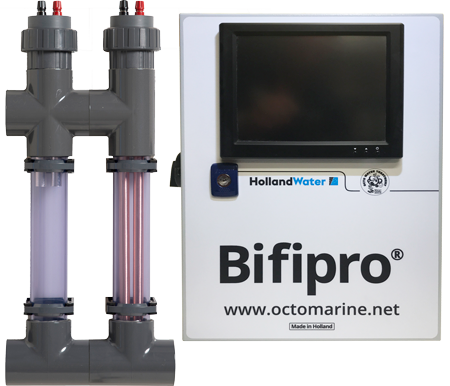

Bifipro® Marine Silver / Copper Sterilizer

Contact Us For Price

The Bifipro® is the “state-of-the art” in sterilization technology. Based on a wealth of knowledge, experience, and continuous R&D.

Employing a unique, patented and technologically superior method of silver/ copper ionization to sterilize and protect the potable water distribution systems and holding tanks.

The Bifipro® is the “state-of-the art” in sterilization technology. Based on a wealth of knowledge, experience, and continuous R&D.

Employing a unique, patented and technologically superior method of silver/ copper ionization to sterilize and protect the potable water distribution systems and holding tanks, helping to remove any existing bacteria and biofilms and preventing possible infection from pathogenic bacteria such as Legionella, E-coli, Pseudomonas aeruginosa and Enterococci.

The use of separate treatment cells, employing separate power supplies, enables ions to be formed without direct complexion, these are continuously measured and controlled by a PLC with an integral data acquisition system, thus providing an audit trail, an invaluable tool in your Fresh Water Safety Plan.

This data can be remotely inspected, verified and the system adjusted, via a GSM or internet link, ensuring your sterilization equipment is always providing you with the highest quality, biologically safe water.

Due to the use of separate copper and silver electrodes, high accuracy flow meters, and patented power control system the Bifipro® is regarded as one of the most advanced copper silver ionization system available.

These benefits combine to enable accurate dosing of copper and silver ions according to flow rate and water quality, ensuring that scaling on the electrodes is minimized thereby extending effectiveness for a longer period.

| Manufacturer | Octo Marine |

|---|---|

| Specifications | Bifipro® Silver / Copper ioniser Parts in contact with water

Bifipro® Control Unit

External Electrical Connections

Maintenance The maintenance depends mainly on the flow of water or consumption of copper and silver. During maintenance the pairs of electrodes are replaced or cleaned and the components of the control unit checked. |